Print Quality¶

No print¶

Only Blank Label Printed¶

- Check in this order:

- Evolabel print head?

If not, remove the fake PH. CPU and connector board must be replaced. - Correct media used?

Direct Thermal or Thermal Transfer - Print Profile Pressure

Press manually to check. - Print head connection

Check the print head cable. Replace if needed. - Replace the print head to determine if it follows the print head

- Replace the CPU to see if it follows the CPU

- Evolabel print head?

Print with quality issues¶

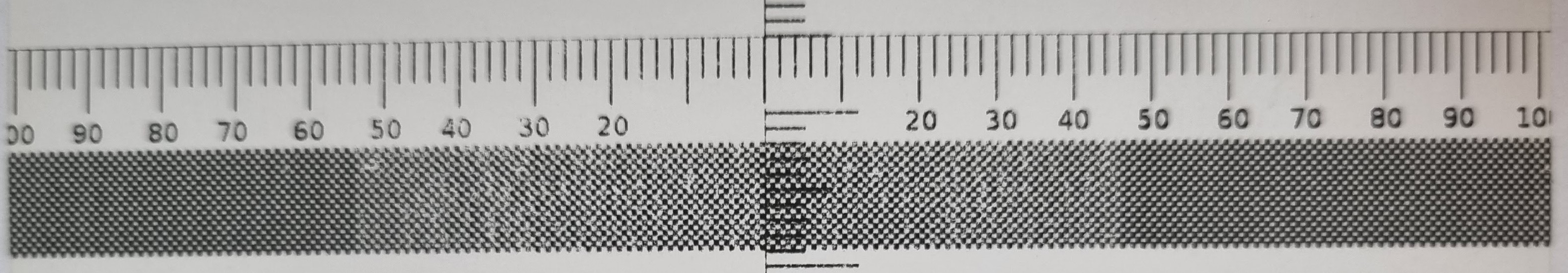

Missing Lines in Print Direction¶

This can be caused by e.g. contamination or build up on the print head. Other reasons may be physical damage or burned out dots on the print head.

- Clean print head with isopropanol.

- Check the print head for physical damage.

- Replace the print head

Areas of Print Missing on the Layout¶

- Print Roller Damaged

An even print head pressure is needed for a good printout quality. A damaged or worn print roll means there is less print head pressure on parts of the media. This results in no or faded print in this area.

- Printhead Not Correctly Aligned in the Print Head Housing

To ensure a good printout, the printhead must be correctly aligned in the printhead housing. Incorrect alignment means that the printhead gets misaligned to the media. This has a negative impact on the heat exchange between the printhead and the media.

Ensure that the holes in the printhead for the printhead housing alignment pins are not damaged. Damaged holes can sometimes be opened up by using a fine sandpaper.

- Check

- The print roller if it is damaged

- That the printhead is correctly aligned in the printhead housing

- If the Ribbon Wrinkles

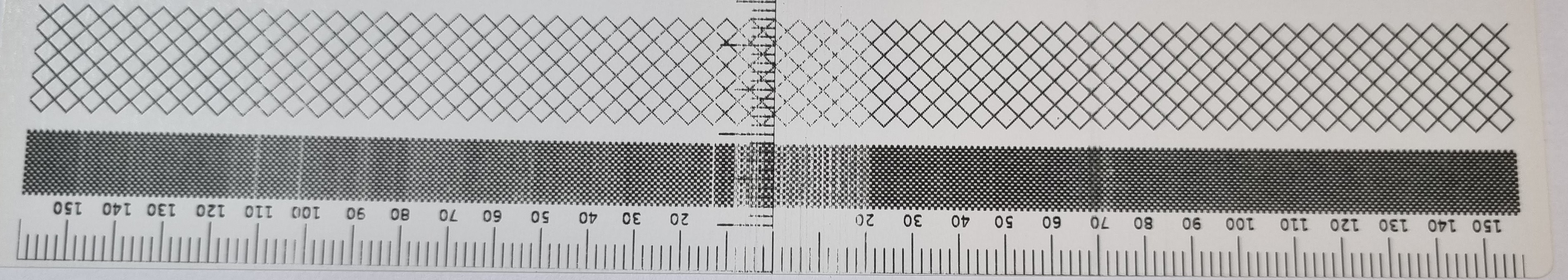

Faded Printout¶

The printout is generally faded or slightly faded at the right or left side in the feeding direction.

- Settings related to print the quality

- Lower the print speed

- Increase the contrast

These two affect each other. When print speed is low the contrast can be set lower, that will improve print head life span. If the line capacity is high then the print speed might need to be high. If the line capacity allows, try to lower print speed down to about 160mm/s.

- Labels and Ribbons

- If the print quality is bad even when using low print speed there could be a problem with label or ribbon quality (if ribbon is being used).

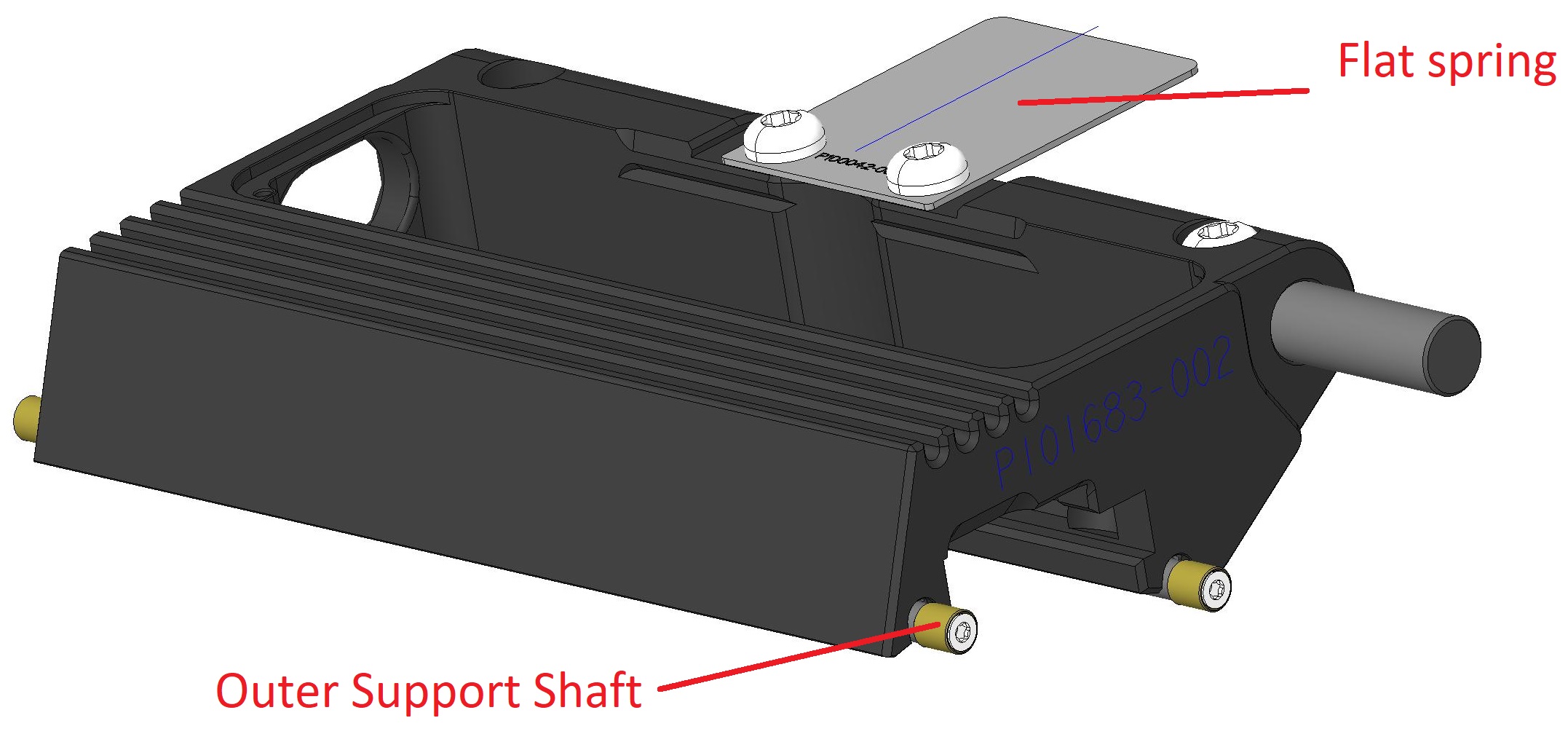

- Flat Spring

- On the top of the print profile there is a Flat Spring plate whose function is to press the print profile down towards the labels. After a while the plate can be bent, e.g. if the printer is hanging upside down, them print profile falls down when opened, or if the print profile is grabbed when lifting the printer. As a temporary solution it may help to flipp the spring plate so the bending is switched from concave to convex. Note that this increases the printhead pressure beyond recommendation which may have a negative effect on the print head life.

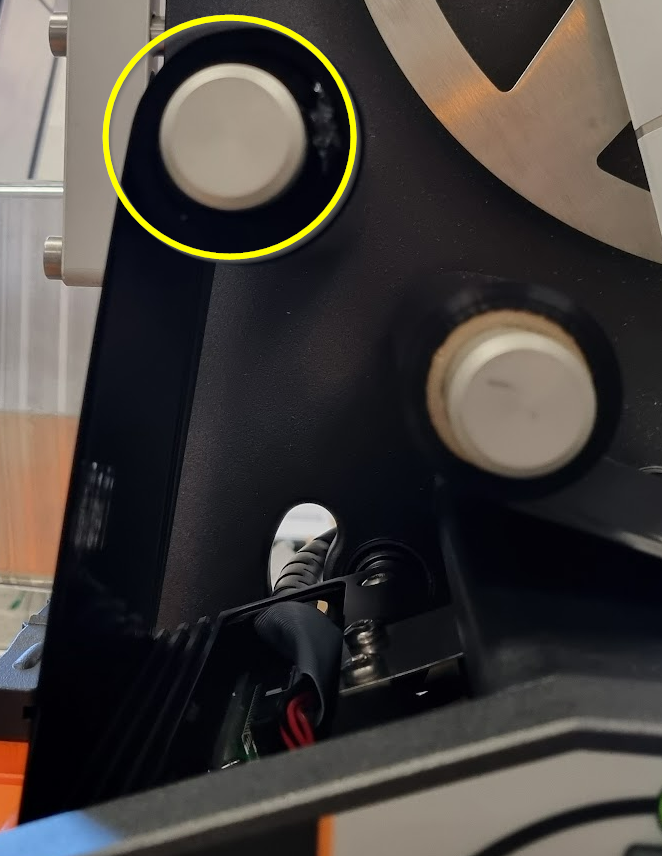

- Outer Support Shaft / Stabilizing Bar (Outer)

- Press on the support shaft (see above), there are springs underneath - so the shaft should be springy and return back to its position when released. It could happen that the shaft is stuck in one end, causing bad pressure and print quality. In this case contact the Evolabel support team.

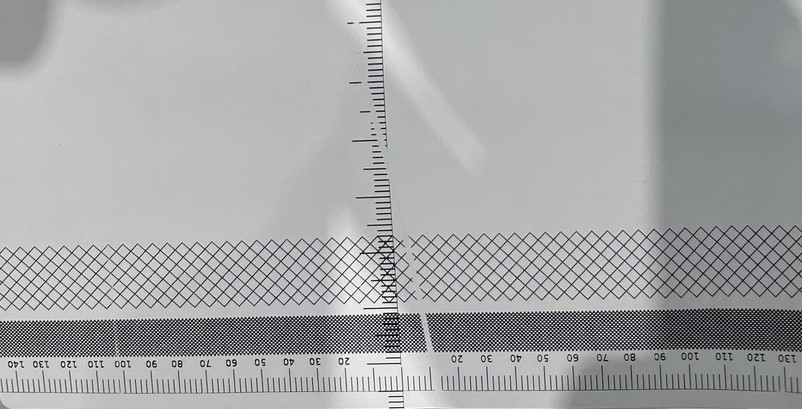

Faded Printout in the Center of the Label¶

A faded printout may be caused by a worn print roll. The worn print roll does not give enough support to produce a high quality printout. This is more pronounced when switching between label widths as the different labels wear the print roll differently.

A worn out print roll could also cause dispensing problems due to skidding of the label lining.

Print Out Compressed¶

The printout gets compressed in the feeding direction.

This is when the media is skidding onto the print roll.

I.e. the media does not move at the same speed as the print roll.

This is usually caused by a unclean, worn or damaged print roll.

Ribbon Wrinkling¶

When using ribbon, thin diagonal lines may be seen on the label. These lines may be caused by ribbon wrinkling.

Start to remove the used ribbon from the rewinder. It’s harder to get a good result if the ribbon already on the rewinder is uneven.

- Ribbon Roller Setup

- The ribbon roller and ribbon rewind roller shafts must be set according to the width of the current ribbon roll. Ribbon wrinkling may occur if the widths are set differently.

- The wrinkling may be cured by the used of settings.

- must be greater than

- The difference between and should not be greater than 10.

- Try to adjust some (and consequently also ), +- 5 to 15 units.

- Layout

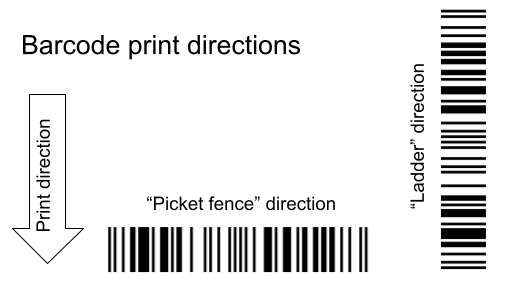

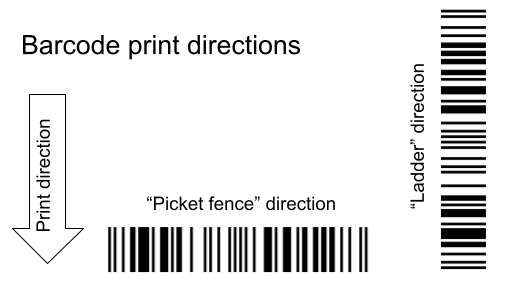

Asymmetric layouts, where there are significantly more black on one half of the printhead may cause ribbon wrinkling. E.g. if there is a ladder directioned barcode close to the label right or left edge.

- Contrast setting

A too high may melt the ribbon. This will not only damage the printhead but also prevent the ribbon from moving at correct speed.

- Other

If this won’t help it may be a printer mechanical issue. You may see wrinkling if the TT rewinder shaft is not parallel to the printhead profile. Verify that the TT rewinder shaft is not wobbly when turning. It may be damaged if e.g. used for lifting the printer. Consult the Evolabel Support team if you suspect an issue with the TT rewinder shaft

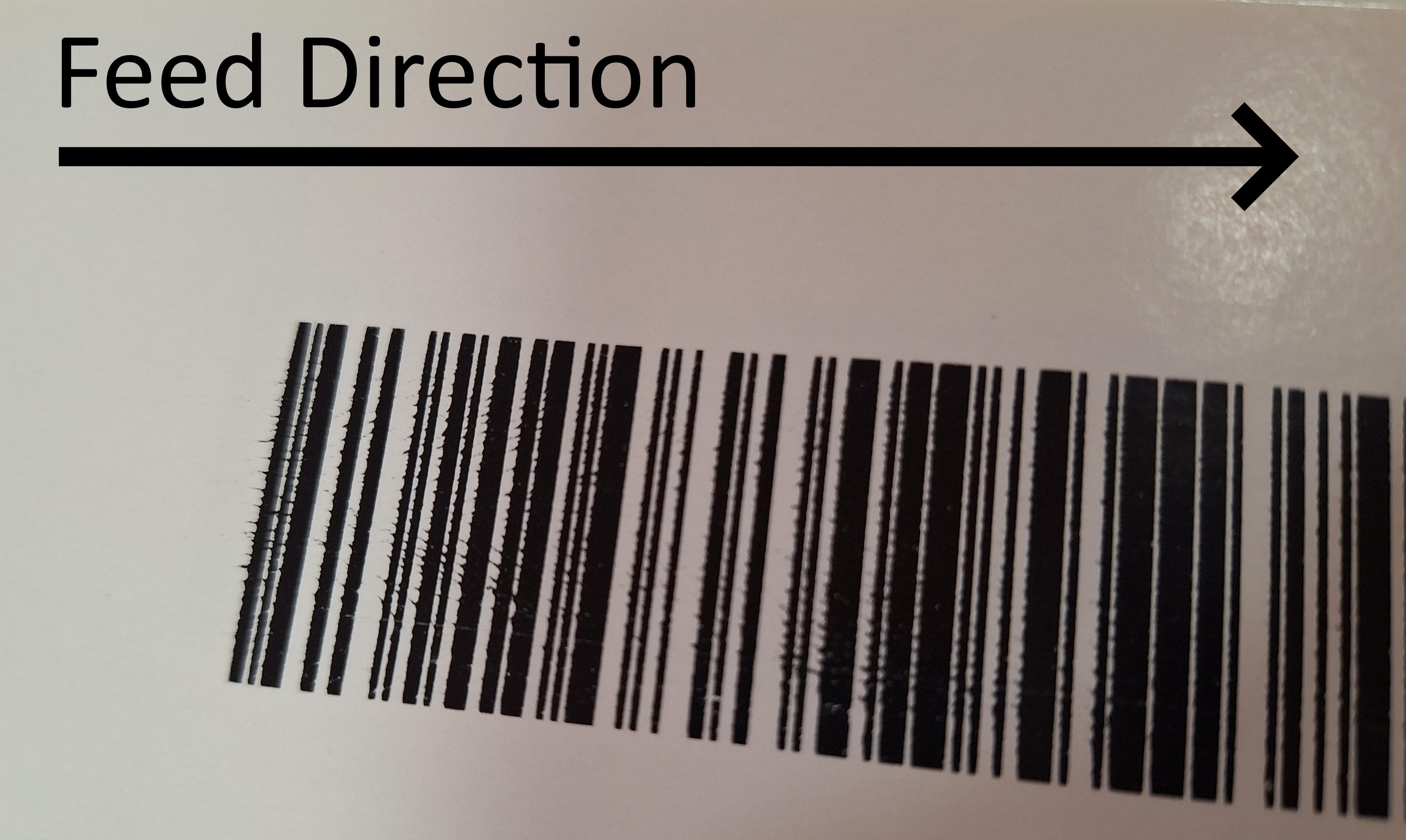

Ribbon Excessive Bleeding/Feathering¶

Only applicable for ribbon printing.

This is typically seen on 1D barcodes printed in the ‘ladder direction’.

Unexpected, thin lines (feathers) after the lines in the barcode.

This is likely caused by an all too high contrast setting. Lower the printer contrast significantly.

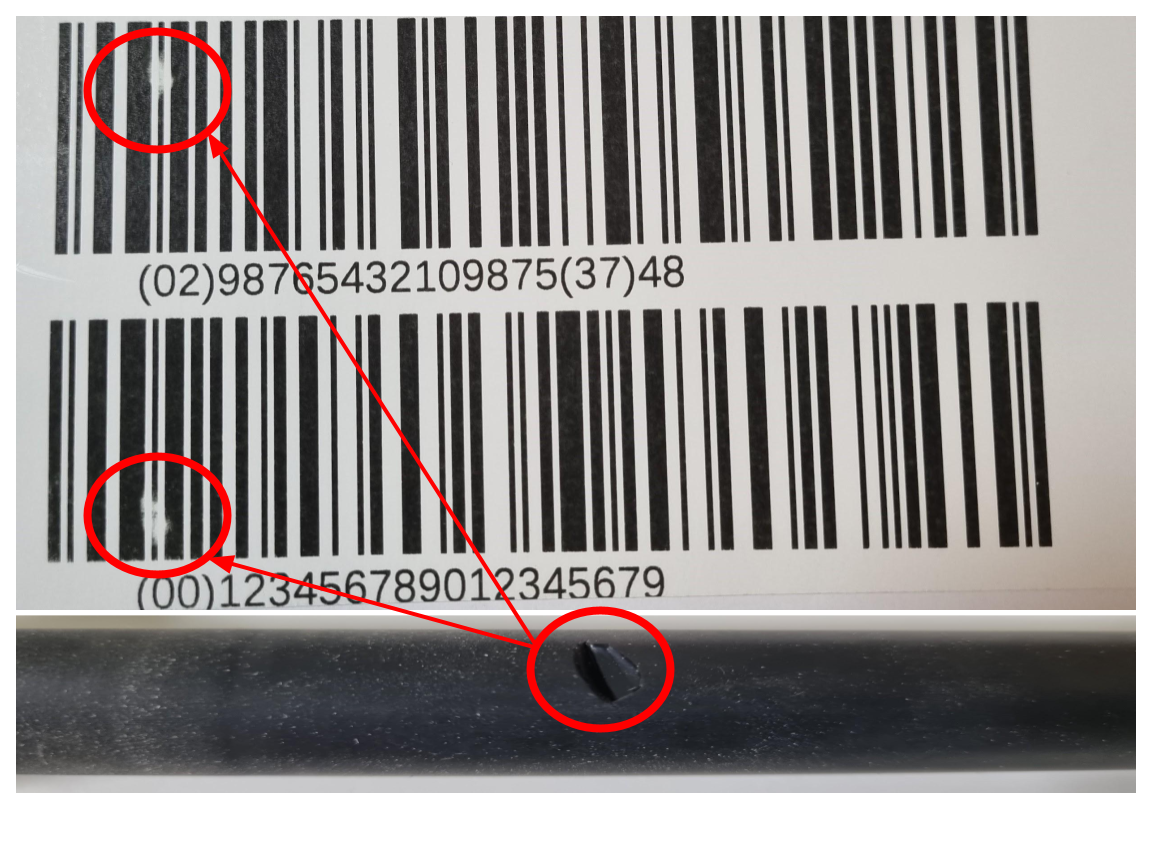

Gray Stripe on Label¶

When using ribbon a gray stripe may appear on top of the label.

The gray line is caused by the ribbon moving at a different speed or direction than the label. To get rid of the line by setting the Ribbon Forward and Backward torque. Increase Forward torque to 35 or more. The perfect setting depends on label size, print speed and ribbon quality.

Other¶

Barcode Quality¶

For good barcode readability, the lines in 1D barcodes and the pixels in 2D barcodes are to be crisp. There should be a distinct difference between black and white with no fuzzy area in between.

How crisp the lines are depends on many factors where the most important are:

- Physical media used

- Contrast

- Print speed

- For thermal transfer printing, the combination of media and ribbon used are also of big importance.

Because of printer physics, it is easier for the printer to print a high quality barcode in ‘picket fence’ direction than in ‘ladder’ direction.

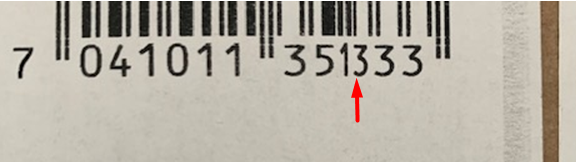

Shifted Printout¶

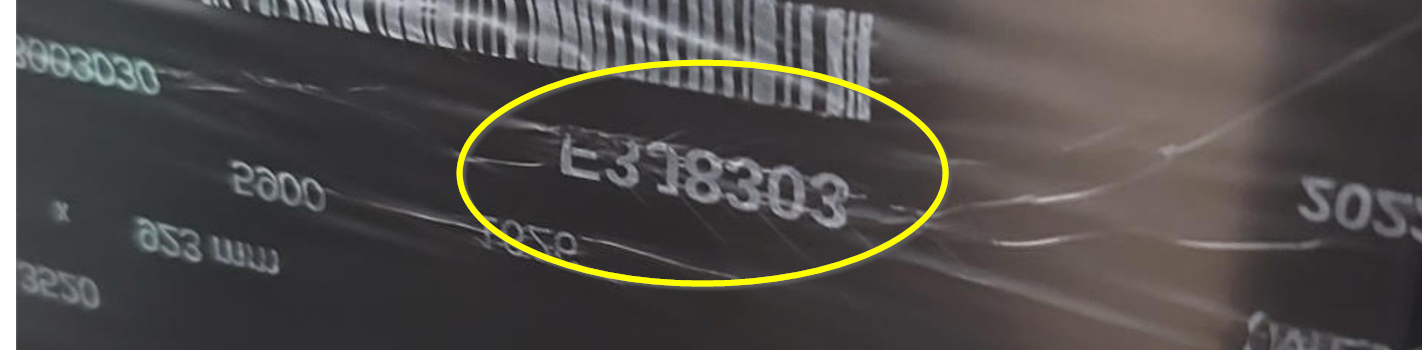

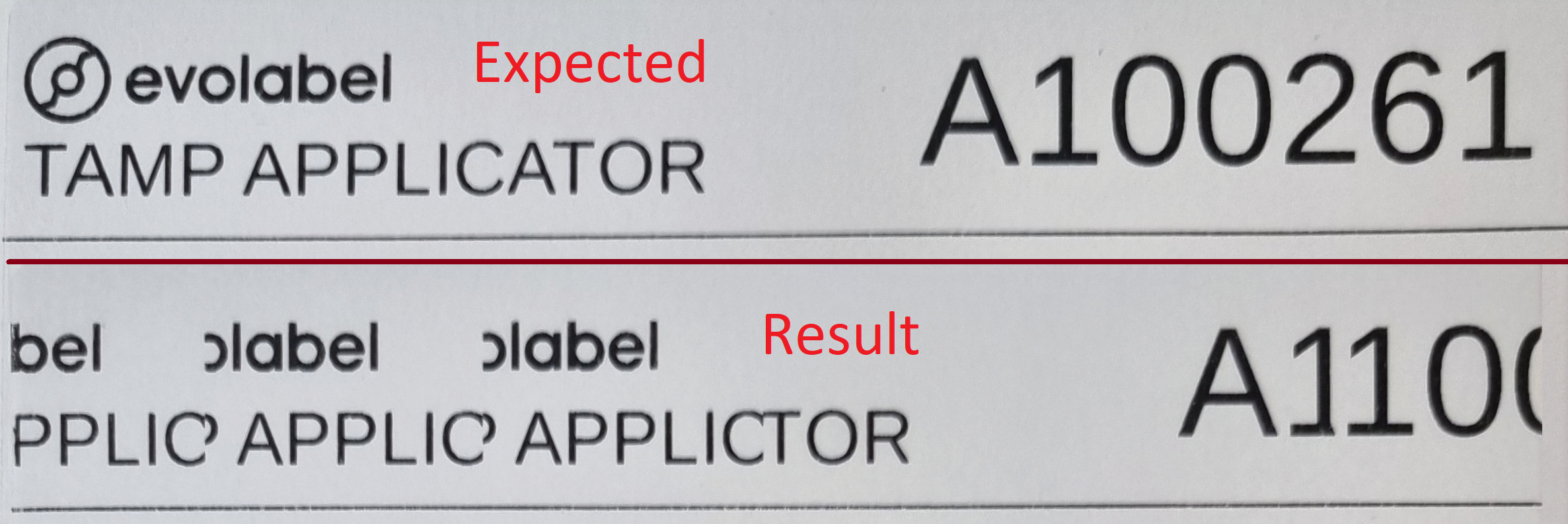

The printout does not look like it should. Parts of the printout are recognized, but printed at incorrect positions.

E.g.

This is a symptom when a printer with an incorrect printhead width has been selected. Verify that the correct model has been selected.