Label Dispensing¶

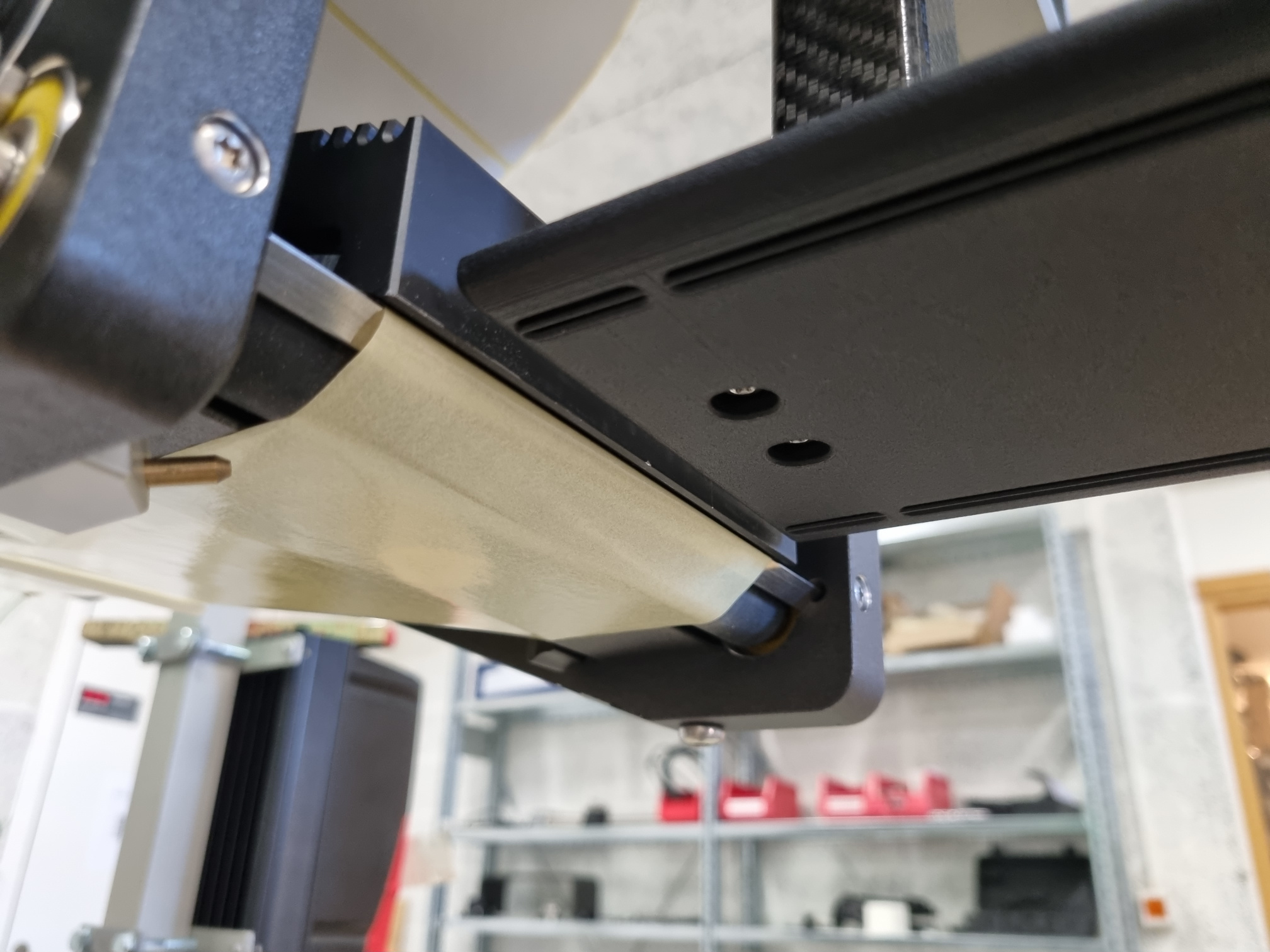

One of the best tools available to fault find label dispensing problems is the video camera in your mobile phone (especially if it has slow motion capabilities). Record a video while printing a few labels. That should reveal if the label dispensing is setup correctly.

Usually a camera position slightly below and in front of the printer give a clear view of the label dispensing.

Example of camera position to record the label dispensing.

Crucial for Good Label Dispensing Are¶

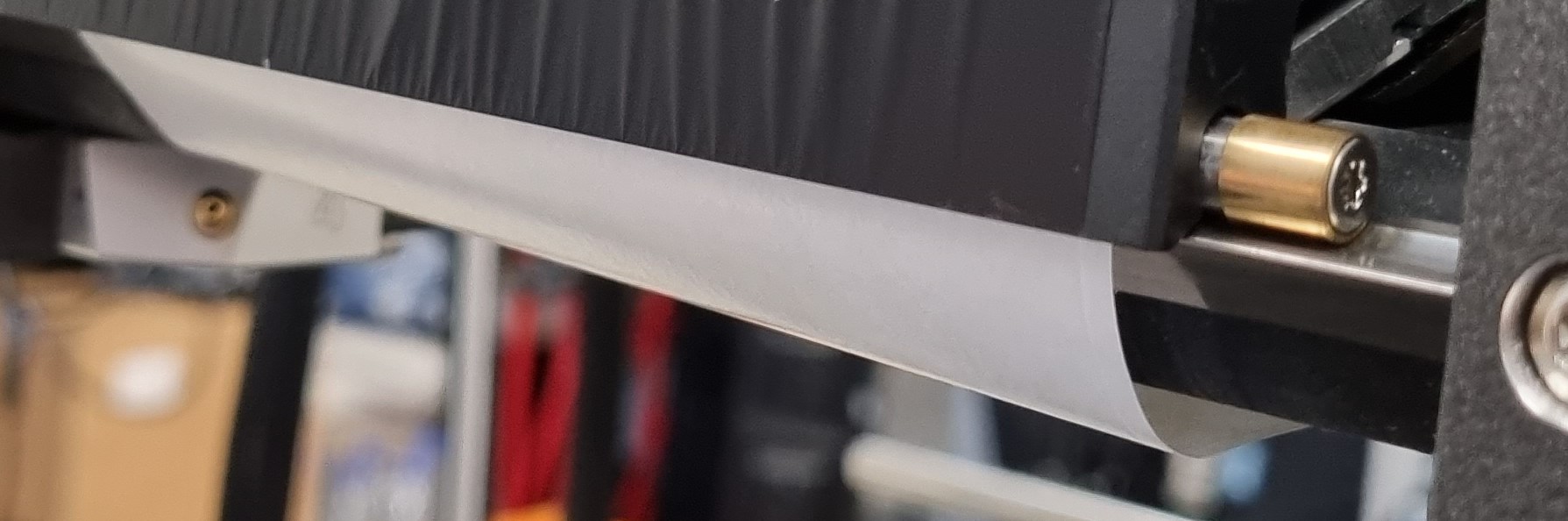

- The Media is Stretched Evenly Against the Dispensing Edge

The labels are dispensed when stretched over the dispensing edge. For this to work all the media must be in good contact with the dispensing edge.

In this example the media is very loose at the right side meaning that the labels will not be dispensed properly.

Make sure that the media guides are properly set on both the media roller and the rewinder.

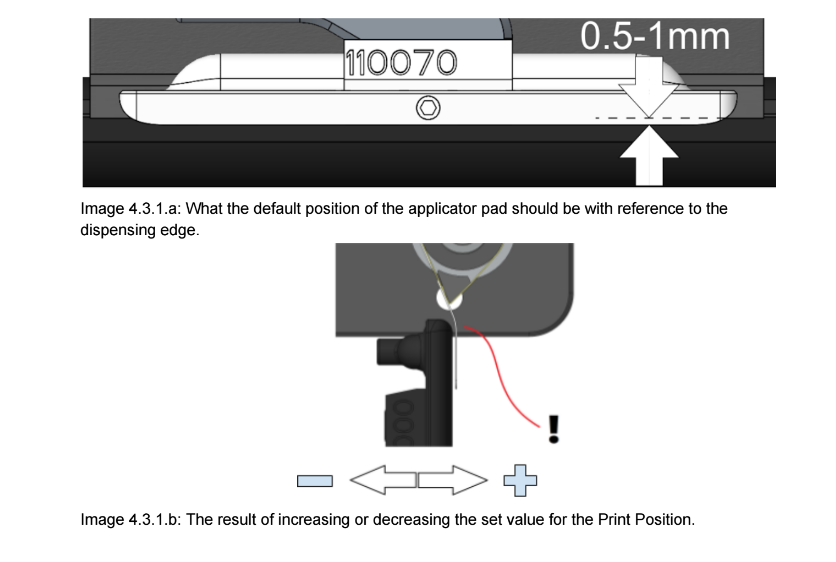

- Right Print Position

If the problem occurs for an applicator with pad - the proper Print position is very important. See applicator manual for correct setting on your applicator. If too far down the label will crash into the pad - if too far up, the label will not be able to reach up the pad.

- Good Function for Support Blow

- Check the air flow through the Support Blow nozzle. If reduced, clean manually with a 1 mm drill. See picture Check air support to the printer - air pressure should be approx. 5.0 bar Check for air leakage Enable the Support Blow Valve () and check if the air is leaking on its way through the printer.

- Clean and Not Worn Print Roll

- Worn or dirty print roll has a very negative impact on the label feed.

- Proper Settings

See printer and applicator manuals for recommended settings that have an impact on the label dispensing.

- Back feed - ().

- If the delay is too short, the label has no time to come loose from the liner before retracted into the printer again. Preferably make a film in slow motion of the dispensing sequence. This shows if the label is fully dispensed out and retracts before it is caught by the vacuum in the pad.

- Media suitable for dispensing

- See Media section in the Label Dispensing tutorial.

Label Falls off the Applicator Pad¶

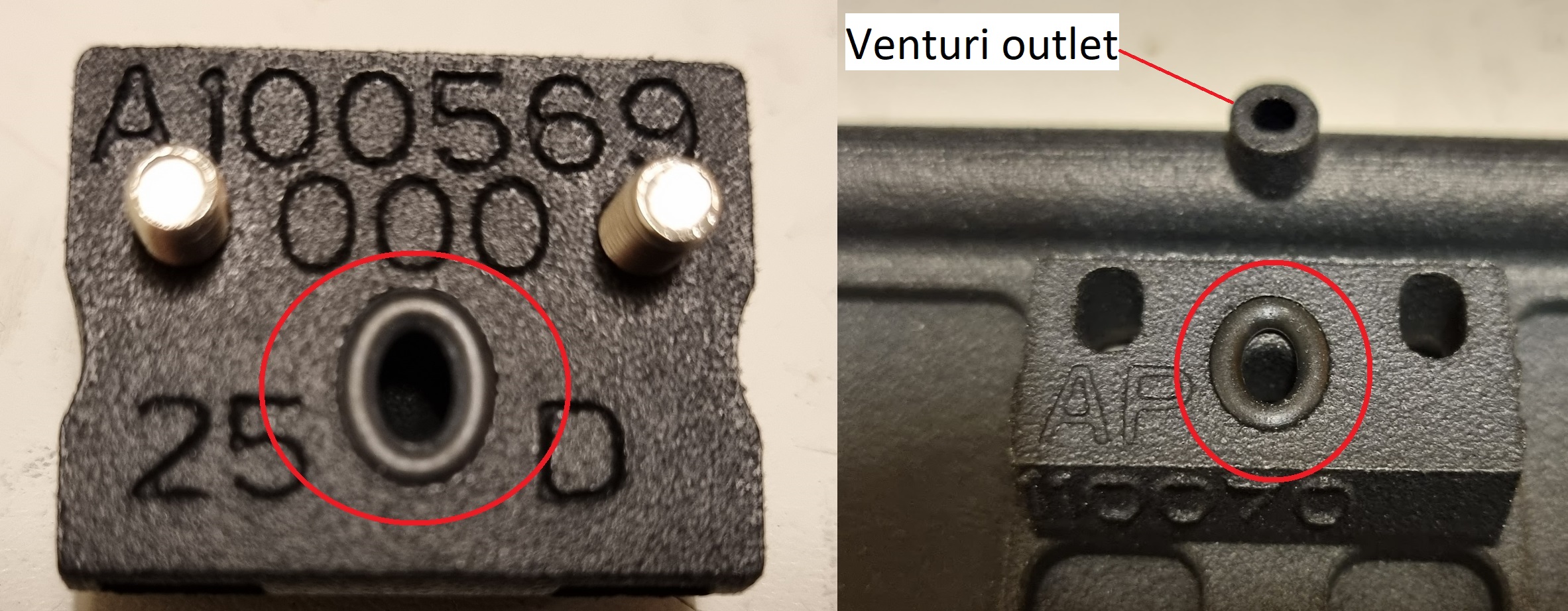

Correct size of applicator pad used

Check air supply to the printer - air pressure should be approx. 5.0 bar

The venturi outlet on applicator pad must not be blocked.

Settings¶

- See printer and applicator manuals for recommended settings that have an impact on the label dispensing.

- Back feed - ().

If the delay is too short, the label has no time to come loose from the liner before retracted into the printer again. Preferably make a film in slow motion of the dispensing sequence. This shows if the label is fully dispensed out and retracts before it is caught by the vacuum in the pad.